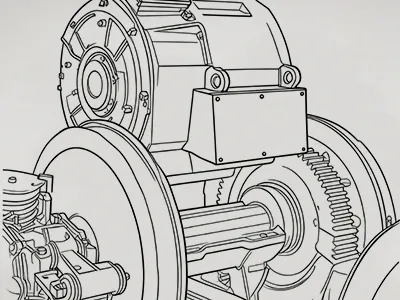

Dynamic Balancing Machines for the

Balancing machines are commonly used for detecting and correcting rotor unbalance during rotation in the electric motor industry. If left uncorrected, rotor unbalance at high speed can cause severe vibration, increased noise, accelerated bearing wear, and reduced overall motor lifespan. By accurately measuring and eliminating unbalance through weight removal, addition, or adjustment, balancing machines significantly reduce motor vibration and noise, improve operational stability, and extend both bearing life and the service life of the motor. This is especially critical for applications such as new energy vehicle drive motors, precision servo motors, and high-speed motorized spindles, where dynamic performance requirements are extremely demanding.