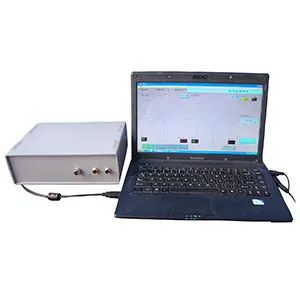

Field balancers are portable devices used to measure and correct unbalance in rotating equipment directly at the installation site. Field balancers let technicians carry out balancing work directly on-site, avoiding the need to dismantle equipment or move it to a workshop. This saves time and helps cut down on maintenance costs. These portable balancing devices work by measuring vibration signals while the rotor is running, identifying the location and amount of unbalance, and guiding the user on how to apply correction.

- Balancing can be carried out on-site without removing the equipment, saving time and reducing repair expenses.

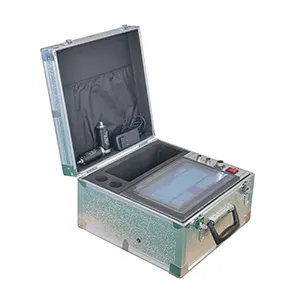

- Compact and lightweight design that is easy to carry and suitable for use across different industrial settings.

- Capable of handling single-plane and dual-plane balancing tasks, and can also be used together with balancing machines for more complex corrections.

Field balancers are commonly used for dynamic balancing of fan rotors, motor rotors, crushers, pumps, grinding wheels, and machine tool spindles, helping equipment run more smoothly and reliably.