YYQ-30

Horizontal Balancing Machine

Hard-bearing balancing machine (belt drive) for workpiece with diameter of up to 800mm and weight of 2-30kg

- Hard-bearing balancing machine combined with frequency converter speed control for flexible adjustment

- Balancing speed can be matched to the actual operating speed of the rotor or component

- Smooth and safe operation without interference from universal joint transmission

- Reduced influence of shaft bending on long rotors, ensuring higher accuracy

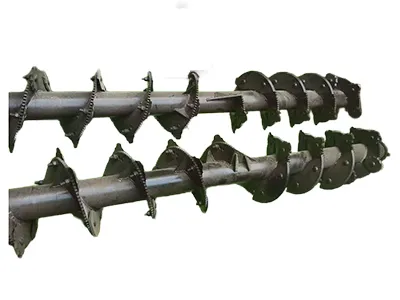

Applications

Suitable for balancing multistage pump rotors and single impellers. It is also suitable for motor rotors, long-shaft parts such as separator and oil press rotors, rollers, and paperboard machine rotors, as well as agricultural machinery components like crushers, straw return machines, and corn harvesters.

Motor rotors balancing

Motor rotors balancing Crusher rotors balancing

Crusher rotors balancing