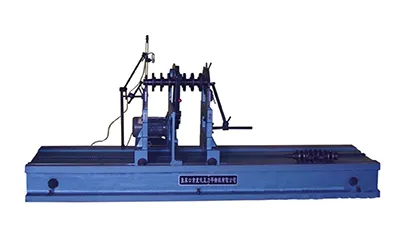

YDQ-160/YDQ-300

Horizontal Balancing Machine

Hard-bearing balancing machine (belt drive) for workpiece with diameter of up to 1250mm and weight of 3-300kg

- Multifunctional hard-bearing balancing machine for the automotive repair industry

- Combines several applications in one machine: crankshaft, driveshaft, wheel, and general rotor balancing

- Hard-bearing structure with belt drive for stable and accurate performance

- Handles workpieces up to 1250 mm in diameter and 3–300 kg in weight

Applications

Used for dynamic balancing of driveshafts, wheels, and crankshafts, providing stable performance and accurate correction during automotive repair tasks.

Driveshafts balancing

Driveshafts balancing Crankshafts balancing

Crankshafts balancing