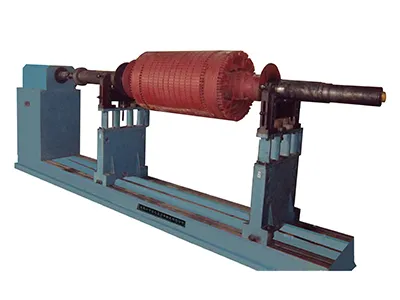

YYW-3000

Horizontal Balancing Machine

Hard-bearing balancing machine (universal joint drive) for workpiece with diameter of up to 2500mm and weight of 100-3000kg

- Balances rotors up to 3000 kg in weight and 2500 mm in diameter

- High-precision measuring system detects unbalance as small as 1 g·mm/kg

- Quick shaft positioning for different rotor sizes

- Dual-plane measurement with real-time digital display for efficient and reliable results

Applications

Used for balancing medium-sized components such as motor rotors, pump rotors, centrifuge rotors, blower rotors, machine tool spindles, and internal combustion engine rotors.

Motor rotors balancing

Motor rotors balancing Pump rotors balancing

Pump rotors balancing Centrifuge rotors balancing

Centrifuge rotors balancing